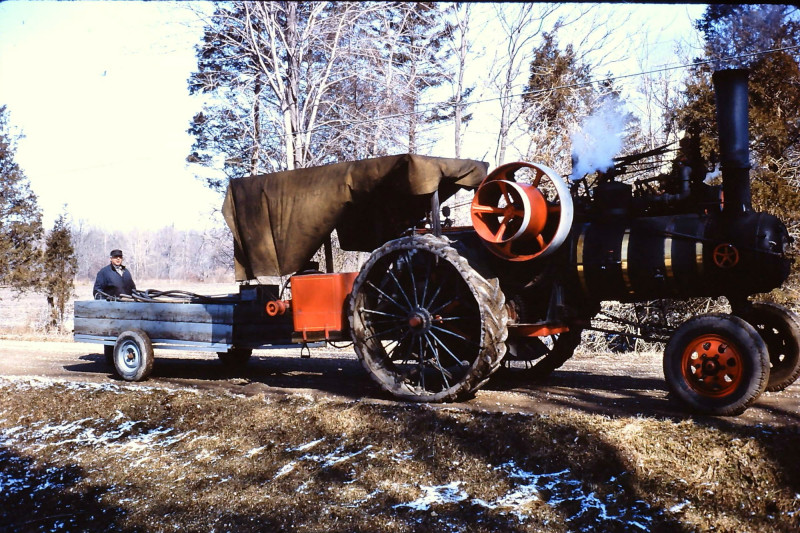

Tons of black iron crept almost soundlessly out of Ernie’s driveway, hissing, smoke billowing, gravel crunching under it’s enormous weight. A mass of levers and gauges allowed the driver to direct the steam power boiling within. At the controls, our cousin Ernie was preparing to drive his steam engine to a local greenhouse where he had been hired to sterilize the soil prior to planting. My father captured these images early one morning in 1972.

Greenhouse soil needs to be sterile – free of weed seeds, fungus, diseases, etc. The process Ernie used, as I understand it, utilized two large metal pans and steam injection hoses. In this photo the pans are loaded in the bottom of the trailer with the hoses piled on top.

The metal pans would be approximately 8 feet long and 4 to 5 feet wide. A pan would be laid upside down on a section of soil with hoses arranged to inject steam into the soil underneath. Keeping the boiler fire red hot with soft coal provided by the farmer, Ernie monitored the gauges and forced steam through the hoses under the pans. With the steam trapped against the soil, the heat would gradually increase until sterilization temperature was achieved. The hoses were then removed and hooked to the next pan which had been prepped and waiting. The hot pan would be left in place while the next was processed, then moved and prepped to avoid any down time. The heating of each one would take at least an hour. Depending on the size of the greenhouse, the job could take days. Steaming soil for sterilization is still one of the methods used by farmers today, but by less magnificent equipment.

Busily feeding the fire, monitoring gauges, steering and watching for traffic, Ernie sets off for the greenhouse.

I would love to hear from anyone who could tell us more about this process. Please share your knowledge!

Very interesting Sue; I had no idea how this was done!

Hi Al, I started out with my Dad’s photos and asked questions at a recent “cousin’s luncheon”. Until then I didn’t realize how the soil sterilization was done – it was a learning experience for me too.